PRODUCT CATEGORIES

CONTACT US

DANBACH ROBOT JIANGXI.INC. Phone:0086-18801818975Tel:0086-0791-88133135

Fax:0086-0791-88221576

E-mail:info@dbhrobot.com

Address:Nanchang High - tech Zone Innovation No. 811

The advantages of automatic loading equipment for industrial robots

DANBACH ROBOT

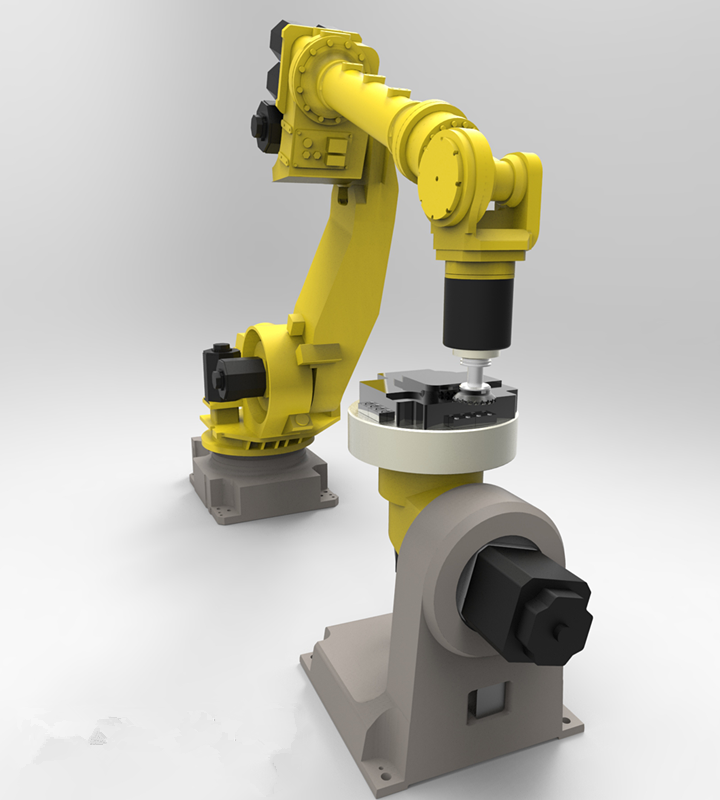

Industrial robots are the source of the third industrial revolution in the world. China's manufacturing industry has begun to transform into automation, and industrial loading robots are becoming more and more widely used. The automatic feeding robot adopts integrated processing technology, which is suitable for loading and unloading of the production line, workpiece turning, workpiece reordering and the like. So what are the advantages of automatic loading equipment?

What are the advantages of automatic loading robot equipment:

(1) High production efficiency: In order to improve production efficiency, it is necessary to control the production cycle. In addition to the fixed production and processing cycle can not be improved, the automatic loading and unloading robot replaces the manual operation, which can control the beat very well, avoiding the impact on the production cycle due to human factors, and greatly improving the production efficiency.

(2) Flexible process modification: We can quickly change the production process by modifying the program and the gripper fixture, and the debugging speed is fast, eliminating the need for training for labor, and it can be put into production quickly.

(3) Improve the quality of workpiece exit: The automatic production line of loading and unloading robots is completely robotized by loading, loading and unloading, which reduces the intermediate links and greatly improves the quality of the parts, especially the surface of the workpiece is more beautiful.

The automatic loading and unloading robot mainly realizes the complete automation of the machine tool manufacturing process, and adopts the integrated processing technology, which is suitable for the loading and unloading of the production line, workpiece reversal, workpiece reordering, etc. It mainly adopts modular design and can be combined in various forms. Form multiple online production lines.

The automatic integration of industrial production and production has been realized, and the equipment has high production efficiency and good quality. The loading and unloading robot is distinguished according to the function of the robot.

Previous:What should be paid attention to the painting robot for plastic parts ?

next:Cost-effective reference and analysis of unmanned agv vehicles